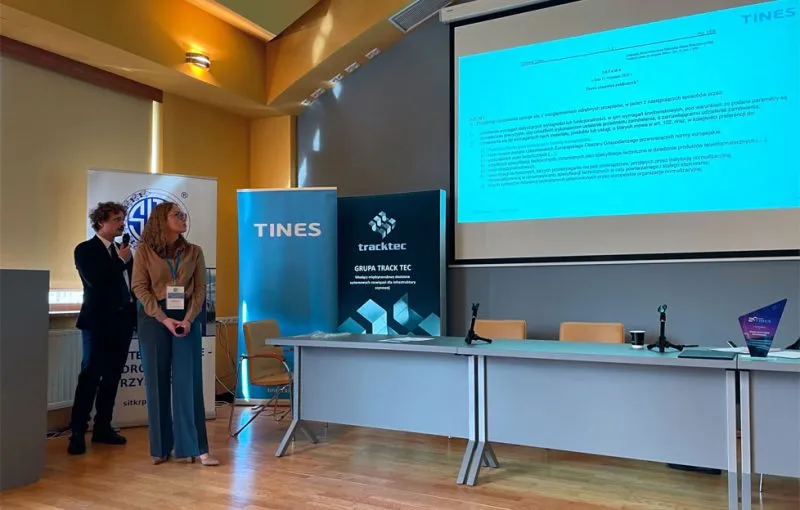

The INFRASZYN 2025 conference, held on 23–25 April in Zakopane, was not only an industry gathering but, above all, a forum for meaningful discussion on responsible railway-infrastructure design.

A highlight of the programme was a talk prepared by TINES experts Magdalena Bodzoń and Michał Rybacki entitled “Vibration-isolation mats in railway track structures – essential product characteristics and in-service properties.”

With higher train speeds and more demanding operating conditions, modern railway infrastructure confronts investors, designers and contractors with numerous challenges related to limiting dynamic loads transmitted from the track to the subgrade and the surrounding environment. One of the key solutions for reducing vibration and noise is the use of vibration-isolation mats – specialised elements incorporated into the track structure.

The performance of these mats depends largely on selecting suitable raw materials and processing methods. Crucial factors include the structure of polyurethane elastomers – their composition and a carefully controlled polymerisation process that determines static and dynamic stiffness, fatigue resistance and dimensional stability. An advanced example is TINES® Rubbermat, which combines SBR/EPDM granulate with a polyurethane binder in precisely chosen fractions and proportions.

Vibration-isolation mats can be classified according to various criteria – material, cross-sectional structure, manufacturing technology or production method – but the most fundamental classification relates to their field of application in different types of rail-track structures. Proven effectiveness hinges on choosing the right testing method and procedure, test conditions and appropriate material-assessment criteria for the intended use.

Comprehensive testing procedures are set out in Polish standards that implement European norms:

- PN-EN 17282:2021-03 Railway applications – Infrastructure – Ballast mats, applicable to vibration-isolation mats installed under ballast in track structures.

- PN-EN 17682:2023-05 Railway applications – Infrastructure – Resilient element for floating slab systems (REFS), applicable to resilient elements in floating-slab tracks.

However, these documents do not specify the parameters governing the functions of resilient elements within the track superstructure; defining those parameters and selecting any optional tests is the purchaser’s responsibility.

Design practice and laboratory studies unequivocally show that effective vibration isolation in rail tracks requires products with well-defined, standardised material properties. Only such products should be specified in tender documents, together with functional requirements and references to current standards.

Real-world implementations include projects such as “Unlocking the Łódź Railway Junction (TEN-T)” and “Construction of a new railway line Podłęże – Szczyrzyc – Tymbark / Mszana Dolna and modernisation of the existing line No. 104 Chabówka – Nowy Sącz,” where TINES® mats have been successfully applied.

We invite you to review the presentation materials:

Read also

Comprehensive construction solutions and ballastless track systems for railways, ensuring effective vibroacoustic insulation and a guarantee of durability for mainline tracks, engineering structures (bridges, viaducts, tunnels, and rail-road crossings).

A comprehensive offer of durable materials for the construction of tram tracks, allowing to reduce the level of vibrations and noise in the vicinity of the route.