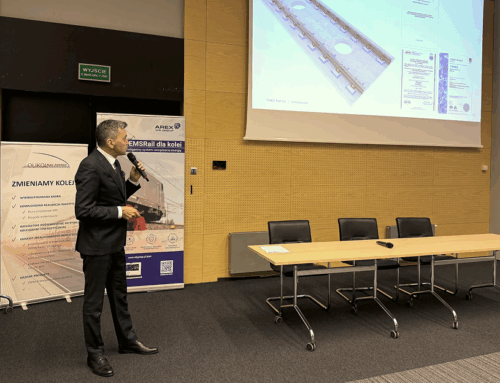

From June 5-7, 2024, the 10th National Scientific and Technical Conference “Solutions for Railway-Road Crossings at Rail Level in Legal, Economic, and Technical Aspects” was held at Hotel Villa Verde in Zawiercie. The event was organized by the Association of Engineers and Communication Technicians of the Republic of Poland (SITK RP).The conference was held under the honorary patronage of Dariusz Klimczak, Minister of Infrastructure, among others. It attracted many distinguished guests and speakers, serving as a platform for knowledge exchange on the conference’s subject matter. The event coincided with the 20th anniversary of TINES, which the company marked by preparing two presentations during the second session of the conference.

The first presentation, “20 Years of TINES’ Commitment to the Implementation and Development of Railway-Road Crossings at Rail Level in Poland,” was delivered by Tomasz Szuba, President of TINES, summarizing the company’s achievements over its two decades of operation.

The introduction to the main presentation delivered by Michał Rybacki was a lecture by Grzegorz Stencel from the Railway Institute, titled “Operational Testing of the TINES® LC-L Integrated Rail-Road Surface. “The topic was further detailed by Michał Rybacki from TINES in his presentation “Operational Testing – Technical Condition of Integrated Rail-Road Surface Elements – Solutions for Identified Issues.” This presentation outlined the results of operational tests conducted on the TINES® LC-L integrated rail-road surface construction. To mark 20 years of TINES, the company commissioned the Railway Institute to conduct independent operational tests on 20 rail-road crossings. The selection of crossings for assessment was determined by the Railway Institute, with a focus on structures experiencing heavy vehicular traffic loads. The tests were conducted in March and April 2024 on 20 randomly selected rail-road crossings and covered the following aspects:

- Track leveling in the crossing area (including transition zones)

- Measurement of geometric track parameters in the crossing area (including transition zones)

- Assessment of the technical condition of the slabs

- Assessment of the condition of rail fastening systems

- Evaluation of the connection between slabs and the adjacent roadway surface

- Assessment of drainage conditions in the crossing area

As a result of the conducted tests, TINES received a detailed 200-page report prepared by the Railway Institute, which confirmed that:

-

The TINES® integrated rail-road surface system provides a durable and stable track structure for railway crossings, ensuring long-term, failure-free operation of the track, even under intense road and rail traffic conditions.

-

The conducted measurements confirm that, in accordance with the requirements for fastening systems, the TINES® integrated rail-road surface system ensures the proper track gauge and rail cross slope. The measured geometric parameters indicate the stability of rail positioning in the TINES® LC-L slab channels and confirm the durability of the TINES® ERS Embedded Rail System fastening, even over time and with continuous operation.

-

The durability of the TINES® integrated rail-road surface system depends on proper subgrade preparation, slab installation, and rail fastening within the embedded system, which should be carried out by specialized companies to meet technological requirements.

-

To ensure high-quality execution, it is recommended that during the construction or modernization of railway-road crossings using the TINES® integrated rail-road surface system, all work should comply with the Manufacturer’s instructions.

-

A critical element of the TINES® integrated rail-road surface system design is the proper planning and execution of transition zones before and after the crossing to minimize threshold effects. Manufacturer-recommended solutions should be used.

-

The drainage system for the crossing should be included in the execution project. It is recommended to use drainage elements provided by the Manufacturer to ensure proper track maintenance in the crossing area. This is especially important for crossings where the condition of access roads contributes to significant soil accumulation due to water and vehicle wheels.

-

Using the TINES® integrated rail-road surface system results in low maintenance costs for railway crossings.

-

Proper maintenance of the TINES® integrated rail-road surface system extends its operational lifespan. Key maintenance recommendations include cleaning the rail groove and clearing water drainage areas.

Read also

Comprehensive construction solutions and ballastless track systems for railways, ensuring effective vibroacoustic insulation and a guarantee of durability for mainline tracks, engineering structures (bridges, viaducts, tunnels, and rail-road crossings).

A comprehensive offer of durable materials for the construction of tram tracks, allowing to reduce the level of vibrations and noise in the vicinity of the route.