Rail fastening is a crucial element in the construction of railway tracks and other transportation infrastructure. Proper rail fastening affects the safety and durability of the entire infrastructure and also influences ride comfort and the noise generated by trains. Over the years, various rail fastening systems have been developed, including the Tines systems. In this article, we will discuss what these systems are and how they work.

Rail fastening in traditional railway tracks

Traditional railway tracks consist of two rails (main rail and cross rail) and ballast, which holds the rails in place. In the early construction of tracks, rails were fastened to the ballast using pegs that were hammered into the wooden ballast. Over time, special metal clips began to be used for rail fastening.

The most popular way of rail fastening is the use of rail clamps. Rail clamps consist of a clip and a bolt with a nut, which are used to fasten the rails to the ballast. Typically, several rail clamps are used per meter of rail to ensure proper grip and stability.

Another method of rail fastening is the use of surface rail fastening. In this system, rails are held in place by special brackets placed on the ballast. These brackets are connected with metal connectors.

Rail fastening using Tines systems

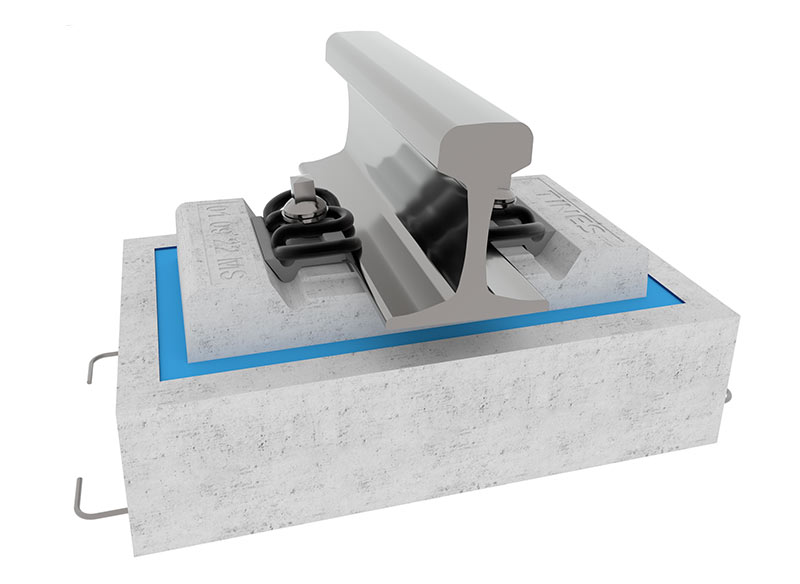

One of the newer and more innovative rail fastening systems is the Tines system. Tines systems consist of blocks placed between the rails and the ballast. Tines block supports have a unique shape, allowing them to absorb vibrations and shocks generated by trains and subway cars.

Tines systems are very popular due to their ability to reduce the noise generated by trains. Additionally, Tines systems are more durable and maintain their properties longer than traditional rail fastening systems and vibrations, helping to reduce the noise and vibrations that affect neighboring buildings and people.

The Tines system is also exceptionally resistant to weather conditions, including temperature and humidity changes. The rubber blocks are made of elastomers, which have thermoplastic properties, meaning they can expand and contract depending on the temperature. In this way, the Tines system can easily adapt to changing weather conditions, helping to maintain the stability and durability of the tracks.

Types of Tines systems

There are many different types of Tines systems, including Tines systems of various hardness and thicknesses, tailored to different types of tracks and weather conditions. These include Tines systems with reinforced metal mesh, which are more resistant to heavy loads, and Tines systems with special collars, providing even better vibration damping.

Other rail fastening systems

In addition to Tines systems, there are also other innovative rail fastening systems developed to improve track safety and durability. One such system is the rail fastening system without the use of clips, in which the rails are held in place by special synthetic rubber pads placed on the ballast.

Summary

Rail fastening is a crucial element in the construction of railway tracks and other transportation infrastructure. Various rail fastening systems have been developed over the years, including the Tines systems. Tines systems consist of rubber blocks placed between the rails and the ballast, which absorb vibrations generated by trains, helping to reduce noise and vibrations. Tines systems are very popular due to their ability to reduce noise, durability, and resistance to varying weather conditions.

It’s worth noting that the choice of the appropriate rail fastening system depends on many factors, including the type of tracks, weather conditions, and the loads that will act on them. Therefore, before making a decision on choosing a specific system, all these factors should be carefully analyzed.

In addition to rail fastening systems, there are also other track elements that are crucial for their safety and durability, such as rails, ballast, sleepers, joint bars, and the traction network. All these elements must be carefully selected and installed to ensure maximum track safety and durability.

In conclusion, rail fastening is one of the crucial elements of railway tracks and other transportation infrastructure. Tines systems are one of the most popular rail fastening systems due to their ability to reduce noise, durability, and resistance to varying weather conditions. However, there are also other innovative rail fastening systems aimed at improving track safety and durability. All these systems must be carefully selected and installed to ensure maximum track safety and durability.

Read also

Comprehensive construction solutions and ballastless track systems for railways, ensuring effective vibroacoustic insulation and a guarantee of durability for mainline tracks, engineering structures (bridges, viaducts, tunnels, and rail-road crossings).

A comprehensive offer of durable materials for the construction of tram tracks, allowing to reduce the level of vibrations and noise in the vicinity of the route.