Vibration in buildings is a significant scientific challenge that, when better understood and studied, can lead to the development of methods for mitigating its detrimental effects on human health, equipment performance, and building durability.

Vibrations in industrial building floors are undesirable due to their negative impact on sensitive equipment and the people inside the building. Typically, for machinery and equipment sensitive to vibrations, as well as for people inside the building, the frequency range from 1 to 100 Hz needs to be considered. In the case of machinery and equipment, knowledge of resonance frequencies is necessary, whereas for humans, frequencies in the range of 5 to 25 Hz are unwanted (the range of internal human organ resonance frequencies). Reducing vibrations in these cases can be achieved by shifting frequencies away from the resonance zone or by increasing the damping coefficient of vibrations. Regarding the impact of vibrations on people, the project will consider both frequency shifting towards safer ranges and reducing the damping coefficient by approximately 10%. In terms of protecting machinery and equipment, especially when resonance frequencies are unknown, the project will mainly focus on reducing the damping coefficient. The fundamental element of the system will be materials from TINES Rail already functioning on the market as sub-ballast anti-vibration mats and recycled materials in the form of rubber granulate. The project’s outcome will be the proposal of potential recipients for industrial flooring systems that can functionally reduce vibrations from both external and internal sources.

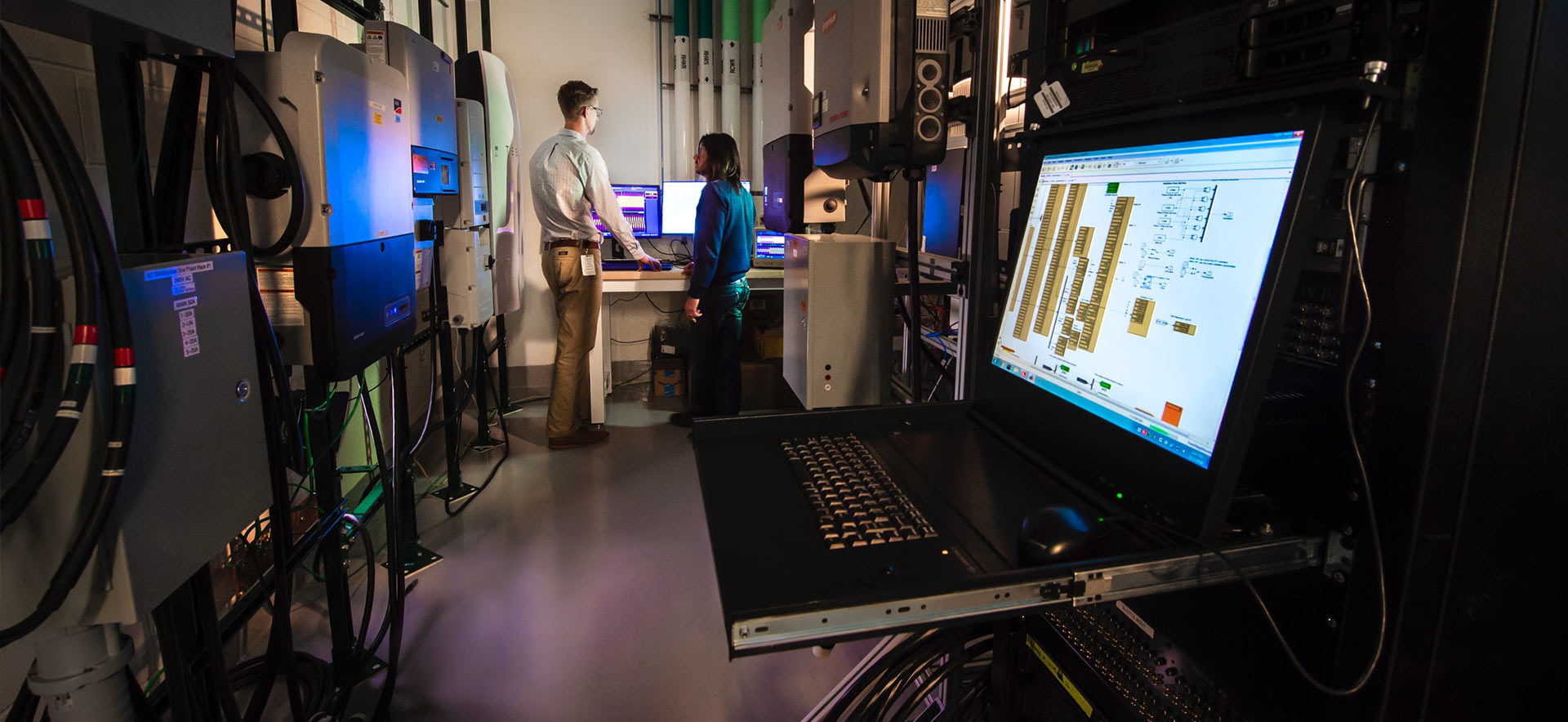

As a result of the project, at least two industrial flooring systems will be developed. One of the floors will have a dynamic insulating layer in the form of an anti-vibration mat located on a structural part of the floor, with a screed of approximately 10-15 cm on top of the mat. This solution is intended for more demanding clients, such as precision laboratories where sensitive equipment must be protected.

The second industrial floor is a product designed for a broader group of recipients, mainly industrial halls located near traffic arteries, where both employees and slightly less sensitive equipment will be protected. This second solution is a floor that uses a formula-based concrete mixture with polyurethane shred granules.

The adopted research methodology consists of several stages. The first stage of the project involves improving TINES® anti-vibration materials. It consists of a laboratory part – testing material properties, an optimization part – optimizing material properties to increase damping properties, and a design part – designing a formula-based concrete mixture. The laboratory part involves determining material parameters in accordance with applicable standards. The optimization part involves calculations to optimize the contribution of individual components in the material, and the design part involves designing a concrete mixture that will increase its damping properties to the desired values. The second stage is computer modeling, aimed at integrating various parts of the technology into a single whole and selecting the best two solutions for further verification through measurements. Subsequent stages include prototype demonstration and its verification through measurements, applying the methodology included in the recently amended PN-B-02171:2017-06 standard for assessing the impact of vibrations on humans in buildings.

Read also

Comprehensive construction solutions and ballastless track systems for railways, ensuring effective vibroacoustic insulation and a guarantee of durability for mainline tracks, engineering structures (bridges, viaducts, tunnels, and rail-road crossings).

A comprehensive offer of durable materials for the construction of tram tracks, allowing to reduce the level of vibrations and noise in the vicinity of the route.