Embedded rail system

TINES® TRAM ERS

System description

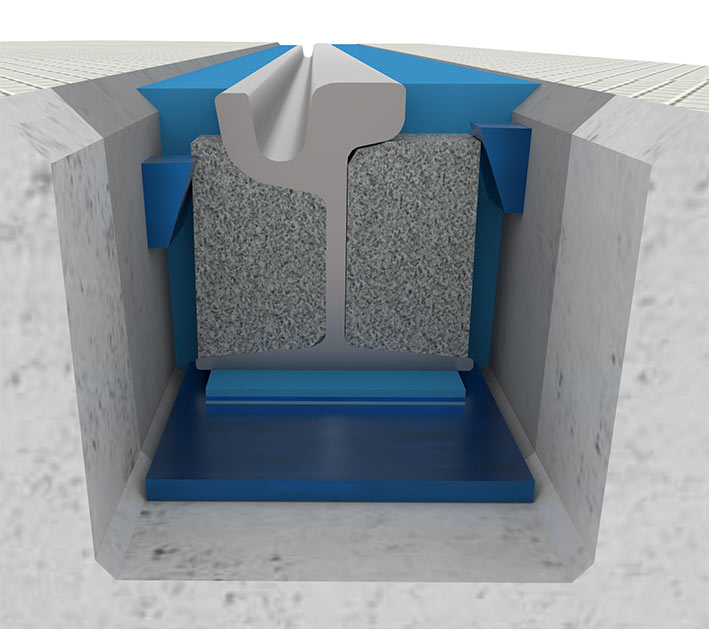

The TINES® TRAM ERS (Eng. Embedded Rail System) rail fastening system is a type of direct rail attachment designed for constructing tramway surfaces in ballast-less track constructions. A prefabricated, reinforced concrete track plate or a wet-poured track plate with formed rail channels is the main load-bearing and geometrically shaping layer for the TINES® TRAM ERS system, replacing the ballast used in ballasted tramway tracks and rail supports, which are most often sleepers.

In the TINES® TRAM ERS system, rails are attached throughout their length in rail channels using the polyurethane elastomer TINES® Polyrail 50/55, which acts as a permanently elastic, homogeneous rail sheath, serving two primary attachment functions, i.e., continuous elastic rail fixation and continuous elastic support for the rail base.

According to the classification of tramway track constructions, the TINES® TRAM ERSrail fastening system belongs to solutions referred to as continuous fastening systems with glued continuous support and continuous rail fixation.

Due to the very good adhesion of the TINES® Polyrail material set to concrete and steel, it is not necessary to additionally fix the rails to the track or steel plate using screw connections.

Continuous rail attachment with TINES® Polyrail material ensures permanent and elastic absorption of loads from tram traffic and from rail temperature changes, i.e., loads acting in vertical and horizontal planes, which are transferred to the main substructure (usually a concrete track plate or steel structure) via the elastic polyurethane elastomer. This makes the TINES® TRAM ERS system effectively dampen vibrations and noise caused by tram traffic on the track.

The permanent material properties of the elastic rail sheath made of TINES® Polyrail 50/55 elastomer also have a beneficial effect on the sheath, fulfilling not only the function of the rail fastening system with the required static and dynamic stiffness but also effective protection of the tramway route environment against stray currents and noise emission. The elastomeric rail sheath also ensures the achievement of the required resistance values against longitudinal and transverse rail displacement, which practically eliminates the risk of track derailment due to thermal forces.

Optionally, in the TINES® TRAM ERSsystem, a continuous, elastic under-rail pad, TINES® Railstrip, can be used, placed under the rail base, which is an additional element reducing the stiffness of rail support and thus positively affecting the vibration isolation efficiency of this system.

Application of the system:

The TINES® TRAM ERS rail fastening system is intended for use in tramway track surfaces on standard-gauge or narrow-gauge tram routes (with track widths of 1435 mm or 1000 mm), on above-ground and underground sections. The system is used for fastening grooved and Vignole rails, including profiles 60R1, 60R2, and 49E1, and block rails with a 57K2 (LK-1) profile. The TINES® TRAM ERS system can be used on straight sections and curves with a radius R ≥ 20 m. The track structure with the TINES® TRAM ERS rail fastening system in the form of a road surface can be used in tram tracks shared with the roadway, in separate tracks (including tram crossings), and built on engineering structures (bridges, viaducts, and tunnels). The system can also be used at pedestrian crossings, bicycle crossings, and switch junctions. The system is particularly dedicated to those sections where it is essential to reduce the level of vibrations and noise emitted to the environment during tram traffic.

Advantages of the TINES® TRAM ERS system:

- low construction height of the tramway surface, especially beneficial in the case of tram route modernization and the resulting structure clearance limitations, and allowing for use on various engineering structures,

- effective noise and vibration dampening from tram traffic to the route surroundings,

- elimination of direct (screw) rail attachment,

- ensuring effective electrical insulation of the rail, necessary to protect the tramway route environment from the influence of stray currents,

- low maintenance costs for the tramway track,

- greater operational durability of the tramway track,

- accurate rail position adjustment during track installation and limiting the occurrence of rail track irregularities,

- technologically simple and quick-track installation,

- protection against the ingress of water and contaminants into the track substructure,

- possibility of adapting vibration and noise damping properties to local design conditions,

- continuous, elastic support for the rail base (no so-called secondary rail deflections),

- possibility of use in switches and intersections,

System components:

Documents:

- National Technical Assessment No. IK-KOT-2023/0175, edition 1, issued by the Railway Institute

- National Certificate of Compliance of Factory Production Control No. 128-UWB-094, issued by the Railway Institute

- System Information Card

- National Declaration of Performance

- Product information cards are included in the system.

For the preparation of a technical and commercial offer, please contact handlowy@tinesrail.com